Our pellet packing machine also applied to pet feed, wood pellets,fertilizer other particulate materials automatic weighing filling packaging.

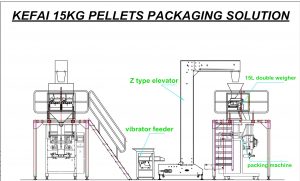

Fully Automatic Vertical Wood Pellet Packaging Machine include

Z-Elevator Vibrating feeder(Automatic Wood Pellet Feeding Machine):

It is automatic quantitative packing system when Z-Conveyor connects with computer weigher and packing machine, great load capacity and height.

The elevator is suitable for elevating solid, such as pellets,grain, food, feed and chemical etc…

Automatic Vertical Forming Filling Sealing Machine Host( wood pellet packing machine)

This pellet packing machine ainly applied to feed, wood pellets,fertilizer other particulate materials automatic bag forming filling sealing packaging.This machine adopts PLC control system, English touch screen, intuitive and easy to understand. Use servo film transporting system, accurate positioning, attractive packaging. Automatic printing from measuring, filling, bag-making, date to the product delivery at once. According to customer needs with a single package and even more bags of cut-off function, you can configure the punching device.

| Modelo | KF02-G 1200 |

| Tamaño de la bolsa | width:300-600(mm) Length:200-850(mm) |

| Velocidad de embalaje | 1-5bags/min |

| Max film width | 1200(mm) |

| Film thickness | 0.04-0.09(mm) |

| Pulling film type | dual belt tension membrane |

| Consumo de aire | 0.8Mpa 0.6m³/min |

| Fuente de alimentación | 220v、50/60Hz、5KW |

| Rango de medición | 5-25L |

| Dimensión | (L)2050×(W)1350×(h)1980 mm |

| Peso | 900 kilos |

Double head linear weigher (Automatic Wood Pellet Weighing Machine)

It’s suitable for weighing pellets, roll or regular shape products such as feed, wood pellets etc.Adopt high precision digital load cell.

* Make mix different products weighing at one discharge;

* Adopt no-grade vibrating feeding system to make products flowing more fluently;

* Program can be freely adjusted according to production condition;

* Can be remote-controlled and maintained through internet;

Finished products conveyor(Conveying Wood Pellet Bag):

The machine can send the packed finished bag to after-package detecting device or packing platform.

Here we will show you a complete wood pellet packing 15kg machine solution design.If you would like to get more details and videos pls contact us now.

- The computer weigher ensure the stable and accurate packaging weight.

- Medium-speed and high-speed machine can be selected, meeting different production requirements.

- The packaging machinecan be equipped witha variety of functional options, such as Alphascope, punching etc.

- The computer weigher can be installed with hopper as required and suitable for different material.

- Each machine has stainless steel and carbon steel structures, suitable for all levels of the customers' requirements.

Semi Automatic Weight Packing Machine Wood Pellets

Our KEFAI 2DC-25K pellet packing machine is mainly suitable for quantitative packaging of pellts, granular powder mixed, strip, block, and other materials. Such as: quantitative filling and packaging of granular materials such as pet feed, fertilizer,wood pellets, pellet sawdust, premix, washing powder, snack food, seeds, grain, hardware and so on.

Ventaja:

PLC control, easy to operate

High-precision electronic scale weighing, high precision

All stainless steel structure, easy to clean and corrosion resistant

Electronic screen or Chinese LCD touch screen for users to choose

Each scale is a two-stage feeding method, with high speed and high precision

Technical parameter:

Single bucket weighing range: 5-25kg

Maximum weighing weight : 30kg

Feeding method :Electromagnetic vibration + pneumatic

Weighing accuracy: ≤±1-5g

Weighing speed: 1-5bag/min

Power current : 2/16 Kw/A

Air source pressure: 0.6-0.8Mpa

Air source consumption 0.5Nm3/min

Single bucket capacity :50L

Weighing method Sensor

Hopper form Double bucket

Frequency/Voltage: 50Hz/60Hz/220V,three-phase five-wire

Dimensions 1650*1000*2600 (mm) (L*W*H)

Machine weight :500kg

Características:

1: The multi-stage feeding and feeding mechanism is adopted, and the weighing range is wide, which can ensure the speed and accuracy of the maximum and minimum weighing;

2: The weighing control system is designed according to the requirements of IP54 (dustproof and waterproof);

3: The machine can be combined with automatic feeding machine, conveyor, sewing machine and automatic control box to form a packaging unit;

4: Double buckets are used for weighing and measuring in turn, which is fast.